I recently bought an Essdee soft rubber brayer to try out for linocut printmaking. It’s the two-inch wide version with a blue handle. If it works well, I’d like to get the four or six-inch roller, too.

New Essdee Soft Rubber Lino Printing Brayer

Welcome to my linocut printmaking blog. I’ve been writing since 2011 so if you’d like to browse or keyword search my archives you can take a look…thanks!

Ink | Paper | Press | Shirts (Fabric) | Tools

I recently bought an Essdee soft rubber brayer to try out for linocut printmaking. It’s the two-inch wide version with a blue handle. If it works well, I’d like to get the four or six-inch roller, too.

New Essdee Soft Rubber Lino Printing Brayer

I’ve been on a search for new brayers (rollers) for lino printing and have bought four since early last year. This includes a 2” Takach hand brayer (35D) and a less expensive 2.4” ABIG inking roller. I’m trying them out on different linocuts and hoping to retire some of my old Speedball soft rubber brayers.

Down the road, I’ll write a long post with a review of brayers - big and small. In the meantime, feel free to send me any questions.

Trying out ABIG and Takach brayers (rollers) for linocut

A little shout-out for a local gem of a store that sells carving tools for woodblock and linocut printmaking, not to mention lots of other types of Japanese hand tools. The shop is called Hida Tool and it’s located on San Pablo Avenue in Berkeley, California. A long time ago, I bought some Power Grip carving tools there and I recently picked up a #1000 grit sharpening stone.

Hida Tool in Berkeley, California

Linocuts are carved and printed from blocks of linoleum. What exactly is printmaking linoleum made of anyway?

Frederick Walton invented linoleum in the mid 1800’s and artists have been using it as a relief printmaking material for over 100 years. It’s a versatile alternative to wood for printmakers. But, most people know linoleum for its use as flooring.

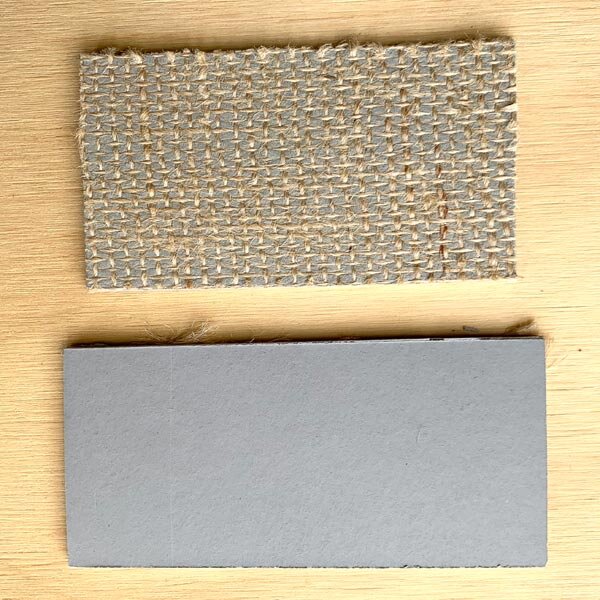

Printmaking linoleum is a relatively thin material, about 1/8” thick, and is available from art supply shops. For purposes of this post, I’m not talking about the soft plasticky blocks like Speedball Speedy-Carve and Speedy-Cut, but rather traditional linoleum. According to a major linoleum manufacturer, art linoleum is made out of the following ingredients:

Linseed oil

Natural rosin

Wood flour

Limestone

Jute (the backing)

Battleship Gray Linoleum Blocks

Battleship gray linoleum is one of the main types of lino that artists carve and print and it’s the type that I’ve used for many years. It does come in other colors, though, like tan. In addition to thin sheets of linoleum, sometimes it comes glued flat (i.e. mounted) to a piece of wood such as MDF.

If you’re curious about the environmental friendliness of linoleum, this Scientific American article talks about some of the green benefits of linoleum flooring, which is essentially the same material as art linoleum, as far as I understand. And, here’s a video about how linoleum is made and a funny little video about its natural ingredients.

Finally, I’ve been inspired by online conversations I’ve had with folks around the world seeking information here on my website about the art of linocut printmaking during the COVID-19 pandemic. Thank you.

I’ve wanted to do a test of papers for hand printing linocuts for a long time and I took it on this year. Though I almost exclusively print with a press, I know most readers and students print by hand, which presents its own challenges. When I help people troubleshoot their printing problems, the choice of paper is sometimes a factor.

There are some specific paper recommendations at the end of this post and I’ve included Blick and Amazon links because they're easy places to order paper. It can be hard to find good printmaking paper at a local art shop. Blick, in particular, has some helpful customer reviews to read if you want other opinions. If you click on their links and choose to buy something, I get a small commission (at no extra cost to you) since I participate in their affiliate programs. You can find more details about this here. But, if you have a favorite neighborhood art supply store, go there by all means or try McClain’s Printmaking Supplies in the US.

Testing papers for hand printing linoleum blocks

If you were to ask me what block printing ink I think is the best, I would give you a couple suggestions and feel pretty confident that it will work for you. Paper is a little different, though. There are so many different types of paper to choose from and what you have available will partially depend on where you live. So, I don’t think there is necessarily a perfect paper for hand printing. But I’m going to give you suggestions on what to look for in paper to help guide you. I’ll also provide some specific recommendations.

Choosing a paper of the right weight is really helpful for printing linocuts, woodcuts or rubber blocks by hand. When you shop you’re going to notice a term on the package or product listing called, “GSM.” This stands for grams per square meter and is a measure of a paper’s weight. The higher the GSM the heavier the paper.

Importantly, if you’re printing by hand instead of a press, you’ll probably want a light to light-medium weight paper. Say, between 30-120 gsm, though this is not a hard and fast rule. You’ll want to avoid really thick paper like Stonehenge (250 gsm) or Rives BFK (250 gsm) when printing by hand, in my opinion. I would say, though, that those two papers are probably my favorites when printing on a press.

To give you a frame of reference for paper weight, I grabbed my pack of inkjet printer paper and it says it’s 75 gsm.

A final print you care about should be printed on acid free paper that will ensure it will last a lifetime, give or take. Here’s a good glossary that defines technical paper terms like acid free, neutral pH and sizing.

I’m reviewing neutral color papers than range from white to tan. Some papers are not nearly as truly white as others!

Paper comes in all sorts of sizes and is sold by the sheet or in a pad. Make sure the paper is a good size for your prints to reduce the amount of wastage. Some paper is of such odd sizes I just don’t feel like it’s much use to me.

Some paper is extremely smooth, while other paper has a more rough handmade feel.

Very generally speaking, lighter / smoother paper will produce more consistently crisp prints with less effort by hand than heavier / rougher paper.

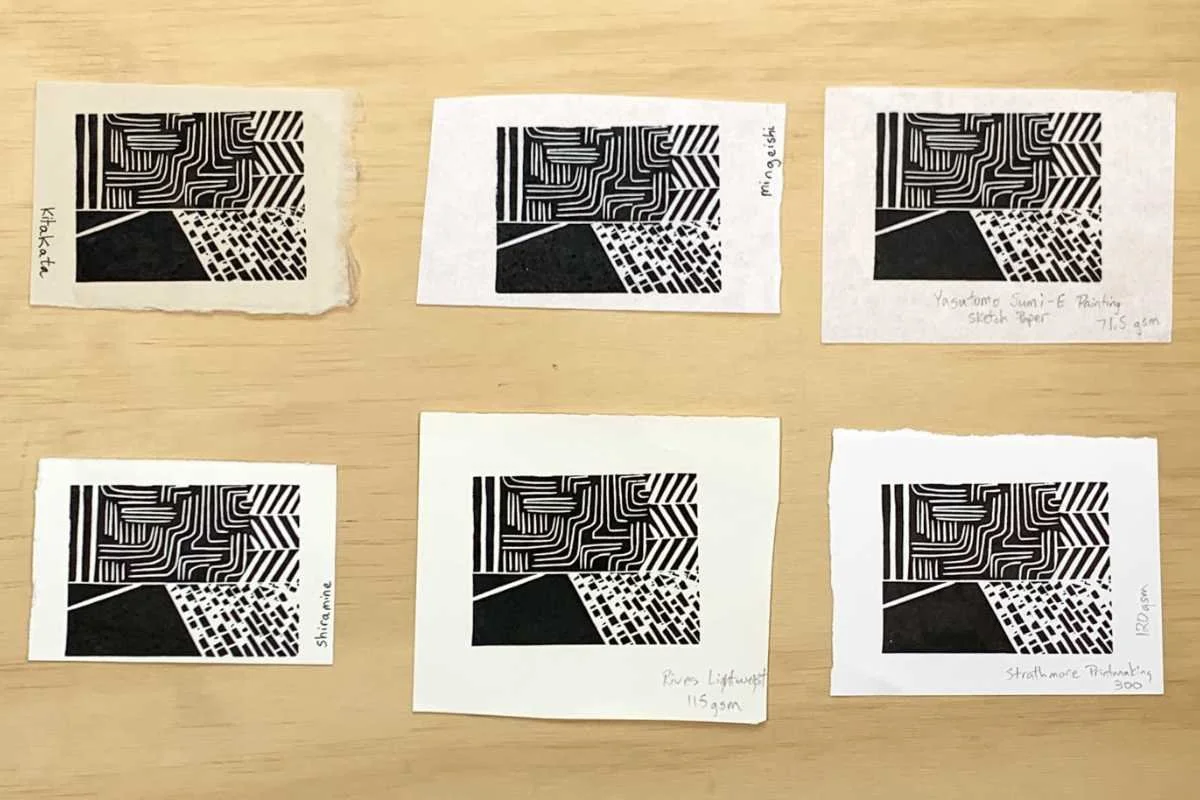

I used a small abstract linoleum block for testing a selection of the most promising papers. All the papers were printed dry. The linoleum block printing supplies I used for the test were:

Caligo Safe Wash Relief Black Ink - (read review)

The back of a metal spoon and/or a Speedball baren to burnish the print

The following are papers that I tried in my studio and found to be worth experimenting more with when hand printing linocuts. I’ve listed them from lightest to heaviest paper.

Six of the printmaking papers I tested for block printing

The lightest papers will be easiest to print consistently by hand. But, you have to be a little more careful with them because they’re thinner. They crease easier, frustratingly, and if you’re too rough when burnishing your prints little bits of the paper can slough off the back.

Kitakata (30 gsm) - a delicate tan paper that comes in 16” x 20” sheets. Beautiful, neutral pH paper that’s competitively priced but thinner than I usually use.

Awagami Mingeishi (45 gsm) - comes in three different colors and in larger sizes than many other attractive options. The paper is a little more see-through than the thicker papers like Rives Lightweight.

Yasutomo Sumi-E Painting Sketch Paper (71.5 gsm) - this is an inexpensive white paper that prints well and comes in pads. I’ve used this on rare occasions over several years. Good for proofing blocks.

Awagami Shiramine (110 gsm) - a new paper for me and I really liked it. It’s off-white. A little on the thicker side, but still produced a nice crisp impression.

Rives Lightweight (115 gsm) - is sold per sheet and comes in medium and large sizes. An excellent, all-around high quality paper. It takes a fair amount of pressure to get a solid print. Keep in mind that even though there are a couple neutral cream-ish colors, none are truly white, in my opinion. Also, this is not to be confused with the 175 gsm option. I’ve printed successfully with this paper on an etching press.

Strathmore Printmaking 300 (120 gsm) - one thing that’s nice about this paper is it’s relatively easy to find in art stores and online. It comes in pads of a range of sizes so it’s ready to use when you buy it. The downside is that it’s about as thick a paper as I would recommend for hand printing. It’s on the upper threshold for weight. It will produce very nice prints if you burnish the print with enough force.

So, there we go, a roundup of some good paper options for hand printing linocuts. They each have pros and cons so one printmaker might find one paper type better than a different person, so please keep that in mind. It’s worth trying a range of papers to see what fits your printing practice and studio / home conditions.

Have fun printing and feel free to contact me with any questions!

I'm a fan of Speedball Fabric Block Printing Ink and have been using it for about three years. I use it primarily for printing linocuts on kids cotton t-shirts and thought it would be helpful to give an update on how the shirts have fared through normal wearing and washing. (Here's my original ink review from a while ago). Since this textile ink isn't widely available, I've included links to Blick Art Materials and Amazon, where it can be purchased. I get a small commission if you end up buying something there since I participate in their affiliate programs but the opinions below (good and bad) are my own. You can find more details about this here.

The washability of inks on textiles is a concern for anyone who starts printing on fabric. Many of us have made a print we're pleased with only to find that it fades a ton upon washing - I know I have and it's frustrating. Some recent questions from readers (thank you!) prompted me to take a close look at a t-shirt I printed years ago and assess how well the linocut print lasted.

My daughter's dragonfly t-shirt is a good example. I printed the linocut on a Bella Baby shirt with Speedball Fabric Block Printing Ink in May 2015. I pulled the shirt out of her drawer this weekend and took a picture.

T-shirt printed with Speedball Fabric Block Printing Ink after almost three years of washing and wearing.

Based on my experience, Speedball's Fabric Block Printing Ink (available through both Blick and Amazon) has performed well in the years since I originally printed the t-shirt. Especially considering that I made this shirt before I did a lot of testing in my printing process. For instance, I now always wash new fabric before printing and cure the ink in a hot dryer (I can't remember if I did either on this early t-shirt). I have a more recent shirt that I block printed after I honed my technique, which is holding up very well.

The shirts were always washed and dried with our regular laundry - no special care was taken with them. The intensity of the lino print still seems good to me. Like I mentioned in my original ink review, though, there is a little fading at the beginning. Don't be surprised when the intensity of the print's color is not as deep after you first wash it.

In my experience, after that initial fading, the ink's permanence holds up over the years. Given this, if the printed t-shirt is going to someone else, I recommend pre-washing the t-shirt once the ink sets, sort of like how companies pre-wash jeans before selling them. And, if you're looking for other printing tips, I have a whole page dedicated to the t-shirt printing process.

I hope this update has been helpful!